Written by Dr. Juan Carlos Díaz Martínez, Underground Engineer, Nevada Gold Mines (USA), Ph.D. in Mining Engineering

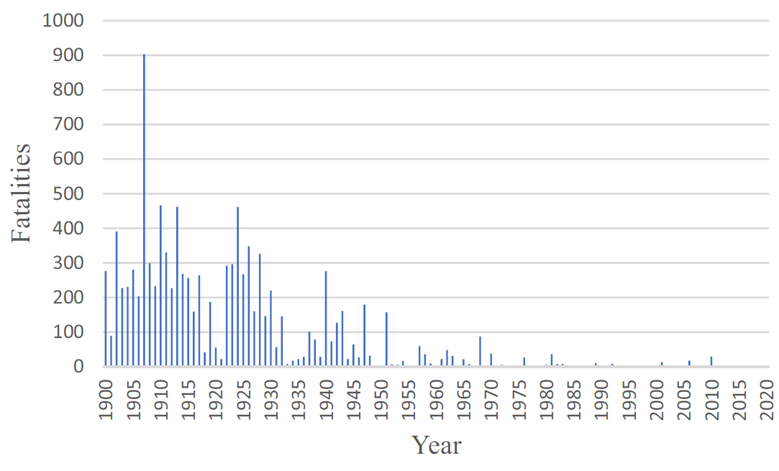

Despite improving mine safety by monitoring and controlling methane gas concentration in underground coal mines, coal miners are still at risk of methane gas explosions while working underground. Explosions in underground mining due to methane gas have been the primary source of incidents and fatalities in the mining industry. According to the National Institute for Occupational Safety & Health (NIOSH), since 1900, approximately 12,000 underground coal mine workers have been killed in over 500 mining accidents only in the USA (see Fig. 1). Around 80% of the accidents, and 90% of the fatalities were related to methane gas explosions (NIOSH, 2020).

In the last decades, the number of disasters and fatalities has decreased due to the remarkable effort made by governmental agencies, the mining industry, and academia to develop state-of-the-art technologies, procedures, and regulations to monitor and more efficiently control methane gas in underground coal mining operations. However, the risk of hazardous methane gas concentrations in underground environments cannot be underestimated. Methane gas still presents challenges to underground coal mines globally. For example, the mining disasters at the Listvyazhnaya coal mine in Russia in November 2021 caused more than 52 fatalities, and at the Soma Coal Mine in Turkey in 2014, which killed 300 miners and is so far considered the worst mining disaster in this century. Also, the latest mining accident at Amasra (Turkey) in October 2022, where more than 40 miners lost their lives (Kozlov, 2021; Düzgün and Leveson; 2018; Hubbard and Timur, 2022). Consequently, underground coal mines must monitor and manage methane gas emissions and concentration to guarantee their personnel's safety. The ability to predict methane gas concentration is crucial in this effort.

Modern underground mine operations monitor and evaluate atmospheric parameters such as temperature, humidity, barometric pressure, gas concentrations, and ventilation parameters (e.g., fan performance and airflow) utilizing Automated Atmospheric Monitoring Systems, which make use of sensors that gather a massive amount of data employed by mine operators to make decisions regarding mine safety and operate ventilation systems more efficiently. In addition, some of these data can be statistically studied to develop forecast models to help improve underground coal mining operations' safety and health parameters.

The research presented in this paper is the result of a Ph.D. dissertation, which the main objective was to investigate potential correlations between methane gas concentrations and independent variables such as barometric pressure and coal production rate to build reliable forecasting models capable of predicting future concentrations of methane gas, mainly based on time series data collected by the Atmospheric Monitoring System of underground coal mining operations in the eastern U.S. and weather data retrieved from public weather stations in the proximity of the case studies.

The mine and weather data were stored and pre-processed using an Atmospheric Monitoring Analysis and Database Management system, also known as AMANDA, explicitly designed to manage Atmospheric Monitoring Systems data. Furthermore, various statistical techniques were implemented to assess the potential association (e.g., autocorrelation and cross-correlation) between the methane gas concentration time series and the independent variables. Such associations were employed to develop univariate and multivariate forecasting models for methane gas emissions in underground coal mines using different time steps (data collected during different time intervals, every 24 hours or 12 hours). Finally, the best model was selected using the Akaike Information Criterion (AIC). The results obtained from the different forecast approaches (univariate and multivariate) were compared using cross-validation metrics to determine the most accurate model.

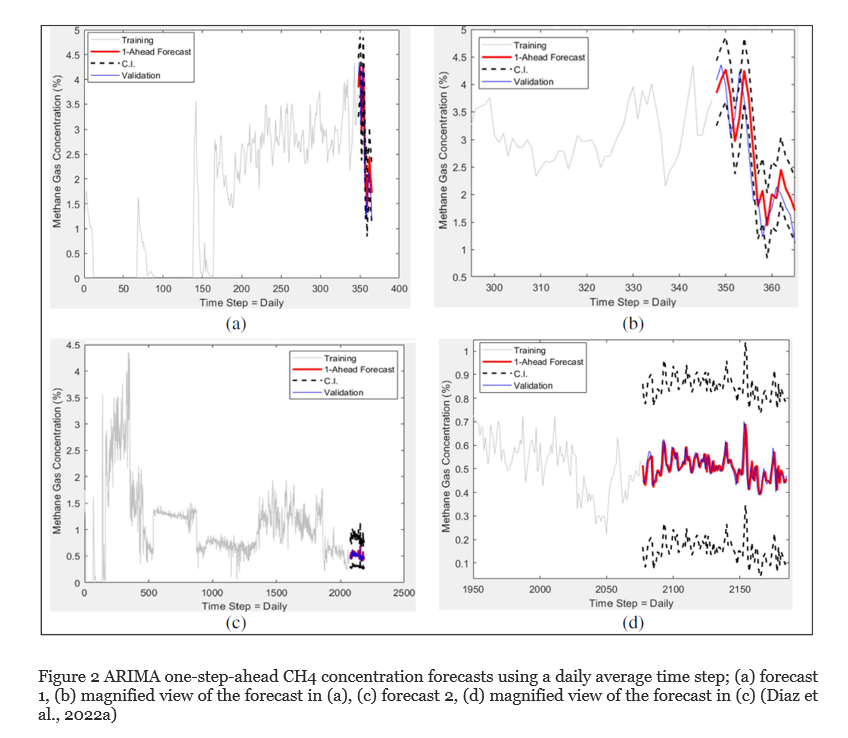

The results presented below were obtained based on a specific forecasting method known as the autoregressive integrated moving average (ARIMA) one-step-ahead model for non-stationary time series. ARIMA is a univariate forecasting technique focused on the concept that the past values of a time series can be employed to predict its future values (Box et al., 2015).

Figure 2 consists of four schemes. Graphs (a) and (c) are the forecasts obtained using the ARIMA(p,d,q) one-step-ahead model, while plots (b) and (d) are amplified versions of the model shown in graphs (a) and (c), correspondingly. The methane time series data used to run the model were retrieved from one of the case studies. The gray line represents the training data (methane gas time series), the upper and lower black dashed lines signify the 95% confidence interval (C.I.), the blue line indicates the time series in the validation set, and the red line represents the forecast. The validation and forecast periods contain about five percent (5%) of points used in the training time series.

Figure 2a shows the forecast for a time series of methane gas concentrations spanning 360 days using a daily average time step. The ARIMA(4,1,4) model was selected based on the lowest AIC value. Figure 2b demonstrates that the one-step-ahead forecast (red line) is quite close to the actual value during the validation period (blue line); the correlation coefficient calculated was R = 0.89, implying a strong correlation between the validation data and the forecasts. Therefore, the ARIMA(4,1,4) model provides an accurate forecast. Moreover, the observed values lie within the 95% prediction interval. Figure 2c displays the one-step-ahead forecast for a time series of methane gas concentrations spanning more than 2100 days (6 years) with a daily average time step. In this case, the ARIMA(3,1,4) model is the best model. Figure 2d demonstrates a strong correlation between the validation data and the forecast, with the correlation coefficient evaluated at R = 0.65. This value is satisfactory, considering that the training data are far from ideal (e.g., they include some sharp fluctuations and zero values), as shown in Figure 2c. Nonetheless, the ARIMA(3,1,4) one-step-ahead tracks the peaks of the validation data reasonably accurately during the validation data lie within the 95% prediction interval. Furthermore, the cross-validations metrics, including the root and mean square error obtained for the one-step-ahead forecast presented in Figure 2c (RMSE = 0.05), are significantly lower than in Figure 12a (RMSE = 0.54), which indicates that the latter forecast is a better estimate (Diaz et al., 2022).

The investigation presented in this article concluded that the forecasting model is improved (a higher correlation between the forecast and the validation data is achieved) by using more extended methane time series (6 years) than shorter ones (1 year) to train the ARIMA model. It can be explained by the methane time series that uses a six-year average time step to contain more information. However, the proposed ARIMA model does not provide a perfect forecasting tool. Other variables may influence the variation of methane gas concentration, such as coal production rate.

It was concluded that the ARIMA one-step-ahead methane gas forecasting method presented in this article, along with an atmospheric monitoring system, provides a solution that could improve underground coal mines' health and safety conditions. Nevertheless, the performance of the forecasting model needs to be further assessed with different datasets and operating conditions.

Improving underground coal mine worker safety is the principal reason behind this investigation. As coal mines continue to operate at deeper horizons and with higher coal production rates, it becomes even more essential to monitor and manage methane gas concentrations efficiently and effectively to avoid or at least decrease the risk of explosions due to hazardous concentrations of methane gas. The dissemination efforts resulting from this research offer the mining industry and academia an excellent opportunity to understand the main steps involved in developing different forecasting methods for the prediction of methane gas concentrations and emissions in underground environments, especially in underground coal mines, as well as the identification of potential research gaps in this field, which should encourage new studies.

For more detailed information about this investigation, please refer to (Diaz, 2022).

Acknowledgements

I would like to thank the following people, without whom I would not have been able to complete this research; first, my advisor, Dr. Zach Agioutantis, for allowing me to work on an exciting and valuable topic for the mining industry. Furthermore, for his permanent support and guidance during this research, I would like to thank Dr. Dionissios Hristopulos.

In addition, I would like to thank the Alpha Foundation for the Improvement of Mine Safety and Health, Inc. for providing the funding to conduct this research.

References

Box GEP, Jenkins GM, Reinsel GC, Ljung GM (2015) Time series analysis forecasting and control, 5th (ed). John Wiley & Sons. New Jersey, United States

Diaz, JC., Agioutantis, Z., Hristopulos, DT., Luxbacher, K., Schafrik, S. (2022a). Time series modeling of methane gas in underground mines. Mining, Metallurgy, and Exploration Journal. https://doi.org/10.1007/s42461-022-00654-5.

Diaz, JC (2022) Development of univariate and multivariate forecasting models for methane gas emissions in underground coal mines. Theses and Dissertations--Mining Engineering. 69. https://uknowledge.uky.edu/mng_etds/69.

Düzgün HS, Leveson N (2018) Analysis of soma mine disaster using causal analysis based on systems theory (CAST). Saf Sci., https://doi.org/10. 1016/j. ssci. 2018. 07. 028.

Hubbard B, Timur S (2022) Coal Mine Explosion in Turkey Kills at Least 41, The New York Times. URL https://www.nytimes.com/2022/10/15/world/europe/turkey-mine-explosion.html, accessed on December 07, 2022.

Kozlov P (2021) Russian coal mine: dozens killed in Siberia accident, BBC News. https:// www.bbc.com/ news/world-europe-59421 319. Accessed December 08, 2022.

The National Institute for Occupational Safety and Health (NIOSH) (2020) NIOSH data and statistics. https://wwwn.cdc.gov/NIOSH- Mining/ MMWC/ MineDisasters/Count. Accessed December 08, 2022.

SHORT BIO

Dr. Juan Diaz Marinez is from Colombia. He holds a bachelor’s degree in Mining and Metallurgical Engineering at La Universidad Nacional de Colombia in 2012 and a master’s degree in Advanced Minerals Resources Development from TU Bergakademie of Freiberg (Germany) and Montanuniversitaet of Leoben (Austria) obtained in 2019. He recently finished his Ph.D. in Mining Engineering at the University of Kentucky (USA). Currently, he is working as an Underground Engineer for Nevada Gold Mines (USA), the biggest gold mine in the world, a joint venture between Barrick and Newmont.

Απαγορεύεται ρητώς η αναπαραγωγή ή αναδημοσίευση, μερική ή ολική, του εν λόγω περιεχομένου. Το RAWMATHUB.GR διατηρεί το αποκλειστικό δικαίωμα δημοσίευσης και παροχής αδειών αναδημοσίευσης κατόπιν έγγραφης άδειας, επιφυλασσόμενο για την άσκηση κάθε νόμιμου δικαιώματος του. Εφόσον επιθυμείτε να χρησιμοποιήσετε το περιεχόμενο, παρακαλούμε επικοινωνήστε μαζί μας στο